Polyethylene (PE) film has gained immense popularity across various industries due to its durability, flexibility, and cost-effectiveness. From packaging to agriculture, this material is widely used to protect products, enhance storage conditions, and improve overall efficiency. Businesses in India, particularly in Ahmedabad, are recognizing the potential of high-quality PE films and are relying on trusted Polyethylene film exporters in Ahmedabad and Polyethylene films suppliers in Ahmedabad to meet their needs. Additionally, PE bag manufacturers in India are increasingly producing specialized polyethylene bags to cater to different industries.

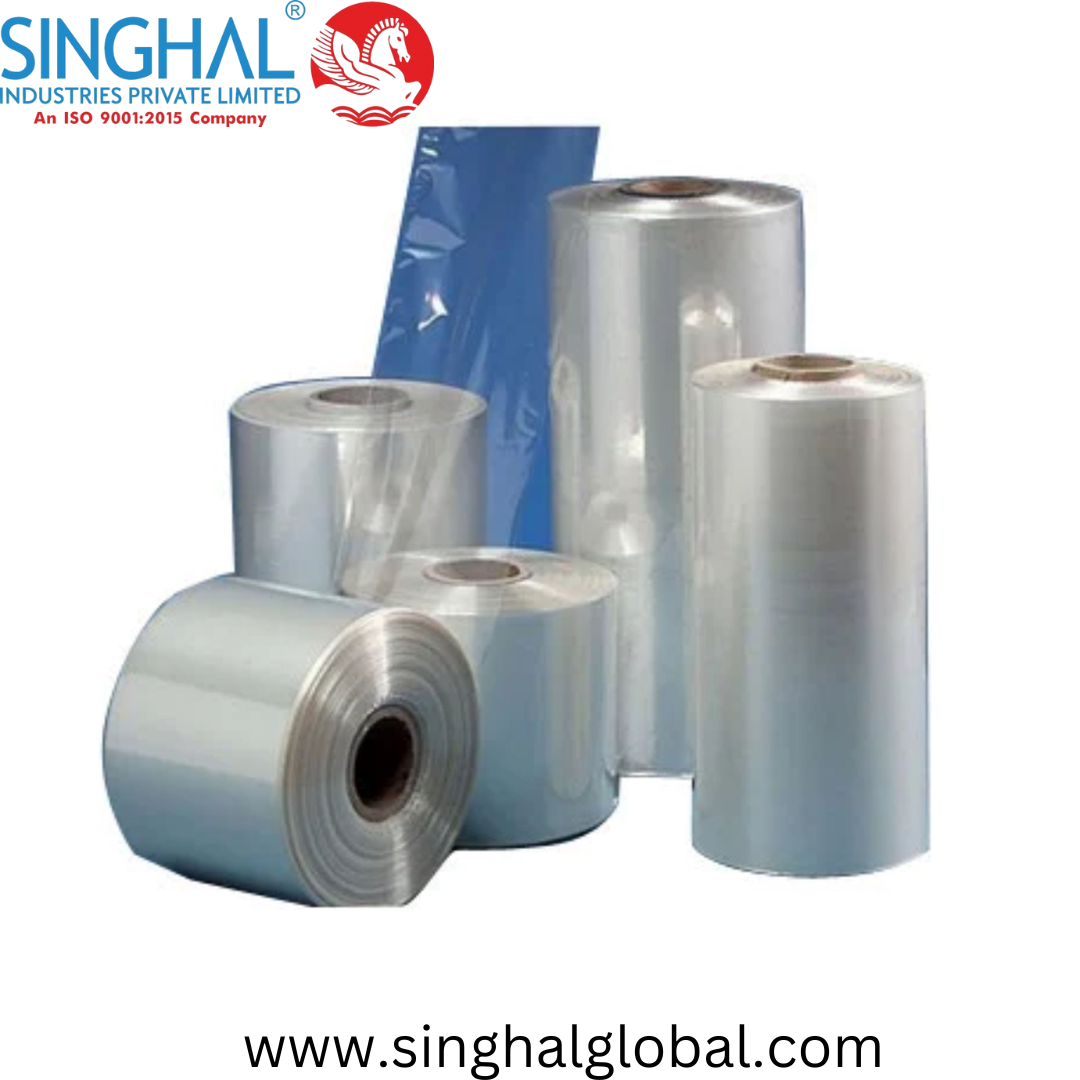

What is PE Film? PE film, short for polyethylene film, is a lightweight, durable plastic film made from polyethylene resin. It is available in different forms, such as low-density polyethylene (LDPE) and high-density polyethylene (HDPE), depending on the intended application. These films are commonly used for packaging, agricultural applications, industrial coverings, and even medical-grade products.

Advantages of PE Film

PE films offer numerous benefits that make them an ideal choice across multiple sectors. Some of these advantages include:

-

High Durability

PE films are known for their exceptional strength and resistance to wear and tear. This makes them ideal for packaging applications where products need protection from external elements. -

Flexibility and Versatility

One of the standout features of PE film is its flexibility. It can be used in multiple forms, such as shrink wraps, protective covers, and stretch films. Whether for industrial packaging or daily household use, PE film adapts to different requirements effortlessly. -

Cost-Effectiveness

Compared to other materials, polyethylene films are highly cost-effective. Their production process is efficient, and the materials required are relatively inexpensive, making them an affordable packaging solution for businesses. -

Water and Moisture Resistance

A key benefit of PE film is its ability to resist moisture. This property makes it an excellent choice for food packaging, agricultural applications, and even medical protective films. -

Eco-Friendly Options Available

With increasing awareness of environmental concerns, many manufacturers are now producing biodegradable and recyclable PE films. This ensures minimal impact on the environment while maintaining the material's benefits. -

Chemical and UV Resistance

PE films are resistant to many chemicals, making them suitable for industrial and laboratory use. Some variants are also UV-resistant, providing protection against sun exposure for outdoor applications.

Applications of PE Film

The versatility of PE film allows it to be used in a wide range of industries. Some common applications include:

-

Packaging Industry

PE film is widely used for food packaging, protective wrapping, and shrink-wrapping applications. It helps keep food fresh and protects delicate products during transportation. -

Agriculture

Farmers use polyethylene film for mulching, greenhouse covers, and silage wrapping. The film helps retain moisture in the soil, reduces weed growth, and protects crops from extreme weather conditions. -

Construction and Industrial Use

PE films are used as protective barriers in construction, providing insulation and moisture resistance in building structures. They are also utilized in manufacturing as part of the production process. -

Medical and Hygiene Products

Medical-grade PE films are used in disposable gloves, surgical covers, and hygiene products to ensure safety and hygiene in healthcare environments. -

Automobile Sector

The automotive industry uses polyethylene films for surface protection during manufacturing and transportation, preventing scratches and contamination.

Why Choose PE Film from Trusted Suppliers in Ahmedabad?

Ahmedabad is a hub for high-quality PE film manufacturing and exporting. Businesses looking for Polyethylene film exporters in Ahmedabad or Polyethylene films suppliers in Ahmedabad can benefit from:

-

Superior Quality Materials: Manufacturers in Ahmedabad use advanced production techniques to ensure high-quality PE films.

-

Competitive Pricing: Due to large-scale production and efficient supply chains, PE films from Ahmedabad are available at competitive prices.

-

Customization Options: Businesses can get PE films tailored to specific requirements, including thickness, transparency, and strength.

Moreover, PE bag manufacturers in India are also expanding their offerings to include specialized PE bags for food, pharmaceuticals, and industrial applications.

Conclusion

Polyethylene film is an indispensable material across multiple industries due to its durability, versatility, and cost-effectiveness. Whether used for packaging, agriculture, or industrial purposes, PE film provides significant advantages, including moisture resistance, flexibility, and eco-friendly options. Businesses seeking high-quality PE films can rely on Polyethylene film exporters in Ahmedabad and Polyethylene films suppliers in Ahmedabad to meet their demands. Additionally PE bag manufacturers in India are continuously innovating to provide tailored solutions for various industries. As demand for sustainable and high-performance materials continues to grow, PE film remains a top choice for businesses worldwide.

Frequently Asked Questions (FAQs)

-

What are the different types of PE films available?

PE films are available in various types, including low-density polyethylene (LDPE), high-density polyethylene (HDPE), and linear low-density polyethylene (LLDPE). Each type has unique properties suited for specific applications, such as packaging, agriculture, and industrial uses. -

How is PE film different from other plastic films?

PE film stands out due to its durability, moisture resistance, and flexibility. Unlike PVC films, which can be brittle, PE films offer excellent stretchability and tear resistance. Additionally, eco-friendly options make them a sustainable choice. -

Can PE film be recycled?

Yes, PE films can be recycled and repurposed for various applications. Many manufacturers now produce biodegradable versions to minimize environmental impact. Proper disposal and recycling programs help in reducing plastic waste effectively.